Endurance Series sails are our most durable product, specifically designed for offshore and passage-making cruisers. Each sail is constructed and reinforced to withstand the rigorous demands of long-distance sailing and prolonged exposure to the elements. The Endurance series is the strong, dependable option for the bluewater cruising sailor.

Strength in the Details

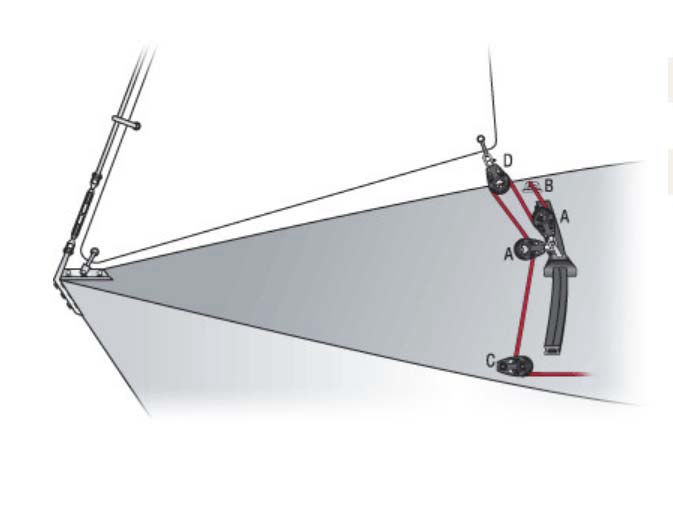

The standard finishing of Endurance sails are an upgraded version of Ullman Sails Navigator cruising sail. These construction upgrades make the sail stronger, which increases durability and adds more miles and years to your sailing enjoyment.• Multiple Rows of Triple-Step Stitching on Every Seam

• Over-Sized Patching at All Corners and Reefs

• U.V. Resistant Thread for All Stitching (seam coating is available)

• Double Leech Tapes

• Additional Reinforcements at Each Slide

• Flutter Patches at Leech of Every Seam

• Heavier, Stronger Slides at Battens and Reef Points

• Stainless Steel Rings with Webbing Load Straps

• Sunbrella U.V. Covers on Roller Furling Sails

Design and Construction

Every Endurance sail is custom designed by the Ullman Sails Design Team to make your boat easier to sail and handle as conditions change. Mainsails have additional reinforcement in high-load areas so you can keep your sails reefed over extended periods of time without damaging the sail.

Sail Cloth (our choice for the Mainsail and JIb)

Woven Cross-cut Dacron: High-quality, high-modulus Dacron is standard in the Endurance Series. Dacron withstands exposure to the elements and high-wind flogging better than any other sail material, providing the greatest longevity of any sail.